PacDrive Training

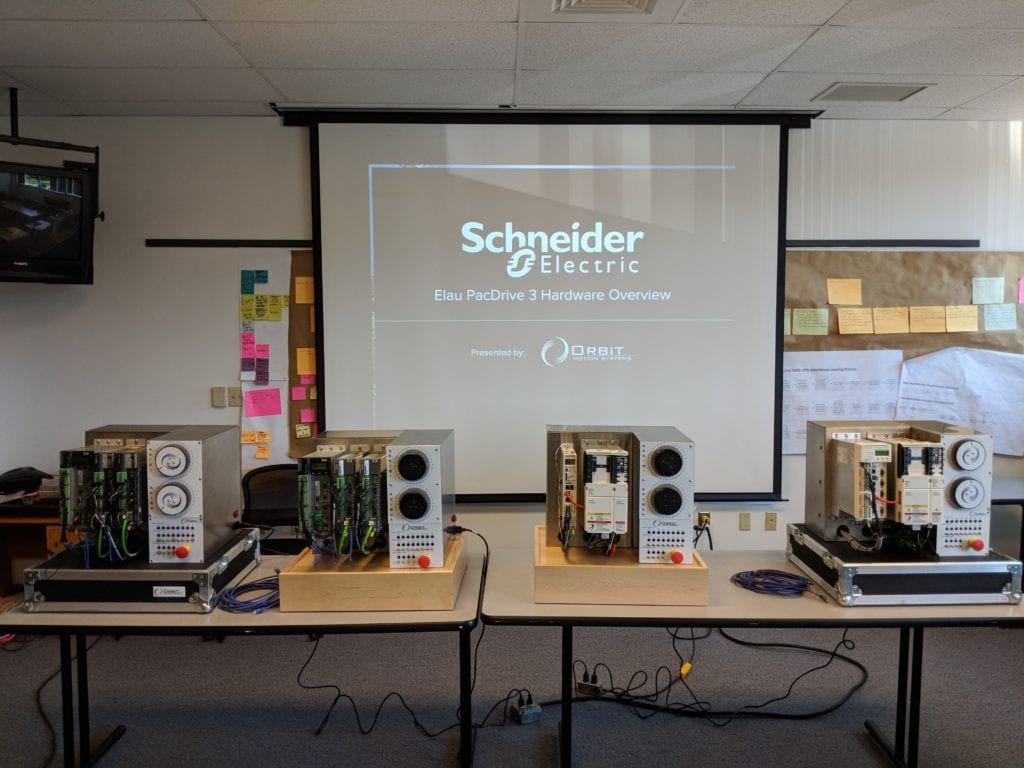

Authorized Schneider Electric PacDrive trainers!

Custom tailored trainings to best serve your needs. Programming, basic service, and hybrid training available for both PacDrive M and PacDrive 3

Schneider Electric PacDrive Training

Basic Service and Basic Programming for PacDrive M & 3 technology

OEM (Original Equipment Manufacturers) & end users will acquire the skills and knowledge to repair and service their own equipment, saving time and money!

Elau training technology:

-PacDrive M (Max-4, C200, C400, C600 series)

-PacDrive 3 (LMC series)

Training Options

Orbit Motion Systems has over 20+ years of ELAU PacDrive experience and is one of the largest PacDrive integrators in the US. Every OMS training is a custom training that is focused on each customers specific needs. There is no mandatory curriculum so time is not wasted on learning information your employees do not need to know. Apart from our custom trainings, each training is performed by an Applications Engineer or Service Technician that has real world experience troubleshooting, programming, and creating solutions featuring ELAU PacDrive Products.

If you have any questions about our trainings, or would like to send us a list of desired outcomes, please contact us on the form below!

Basic Service Training

- Electricians & Maintenance Personnel

- Learn about skills & methods for providing service & maintenance to PacDrive machinery

- Acquire the ability to recognize & fix common hardware failures in PacDrive machinery

- Acquire the ability to test & troubleshoot real world scenarios without supplemental training units

- PacDrive Diagnostics (PDM & PD3)

- Obtain & interpret diagnostic files

- PacDrive Backup (PDM & PD3)

- Obtain, manipulate, and download program backups

- PacDrive Sercos Firmware Assistant (PDM)

- Modify existing PDM Hardware firmware (ex. MC-4 Drive Firmware)

- PacDrive Netmanage (PDM)

- Connection to PDM devices

- PacDrive service training is the most useful to a companies service & maintenance staff

- Recommended Training Class Size: 2-4 Participants

- Maximum Training Class Size: 6 Participants (with additional fees)

- In-House & On-Site Training offered

- Introduction of Schneider Electric PacDrive products

- Learn the various Schneider Electric Service tools

- Test skills of service tools on PacDrive training unit

- Test skills of service tools on customers systems (On-Site only)

- Diagnose errors on our PacDrive training units

- Real-life simulations performed by OMS trainers on training units

- Additional topics can be covered based on customers request

Advanced Service Training

- Maintenance Personnel & Controls Technicians

- Learn about skills & methods for providing service & maintenance to PacDrive machinery

- Acquire the ability to recognize & fix common hardware failures in PacDrive machinery

- Acquire the ability to test & troubleshoot real world scenarios without supplemental training units

- Utilize the programming environments to better diagnose PacDrive machinery

- PacDrive Diagnostics (PDM & PD3)

- Obtain & interpret diagnostic files

- PacDrive Backup (PDM & PD3)

- Obtain, manipulate, and download program backups

- PacDrive Sercos Firmware Assistant (PDM)

- Modify existing PDM Hardware firmware (ex. MC-4 Drive Firmware)

- PacDrive Netmanage (PDM)

- Connection to PDM devices

- Automation Tool-Kit EPAS-4 (PDM) & SoMachine Motion (PD3)

- View training unit program

- Learn to navigate EPAS-4 & SoMachine Motion

- Learn how to perform Scope Traces

- Learn how to perform Y-Offset (Utilized to move one Axis)

- PacDrive advanced service training is the most useful to a companies controls technicians & maintenance staff

- Recommended Training Class Size: 2-4 Participants

- Maximum Training Class Size: 6 Participants (with additional fees)

- In-House & On-Site Training offered

- Introduction of Schneider Electric PacDrive products

- Learn the various Schneider Electric Service tools

- Test skills of service tools on PacDrive training unit

- Test skills of service tools on customers systems (On-Site only)

- Diagnose errors on our PacDrive training units

- Real-life simulations performed by OMS trainers on training units

- Utilize the program environments to have a deeper understanding of Machine’s program

- Utilize the program environments to troubleshoot Machine Faults

- Additional topics can be covered based on customers request

Programming Training

Original Equipment Manufacturers

- Learn about skills & methods for providing service & maintenance to PacDrive machinery

- Acquire the ability to recognize & fix common hardware failures in PacDrive machinery

- Acquire the ability to test & troubleshoot real world scenarios without supplemental training units

- Utilize the programming environments to better diagnose PacDrive machinery

- EPAS-4 Programming Software (PacDrive M)

- SoMachine Programming Software (PacDrive 3)

- Recommended Training Class Size: 2-4 Participants

- Maximum Training Class Size: 6 Participants (with additional fees)

- In-House & On-Site Training offered

- Introduction of Schneider Electric PacDrive products

- Learn the various Schneider Electric Service tools

- Test skills of service tools on PacDrive training unit

- Test skills of service tools on customers systems (On-Site only)

- Diagnose errors on our PacDrive training units

- Real-life simulations performed by OMS trainers on training units

- Utilize the program environments to have a deeper understanding of Machine’s program

- Utilize the program environments to troubleshoot Machine Faults

- Additional topics can be covered based on customers request

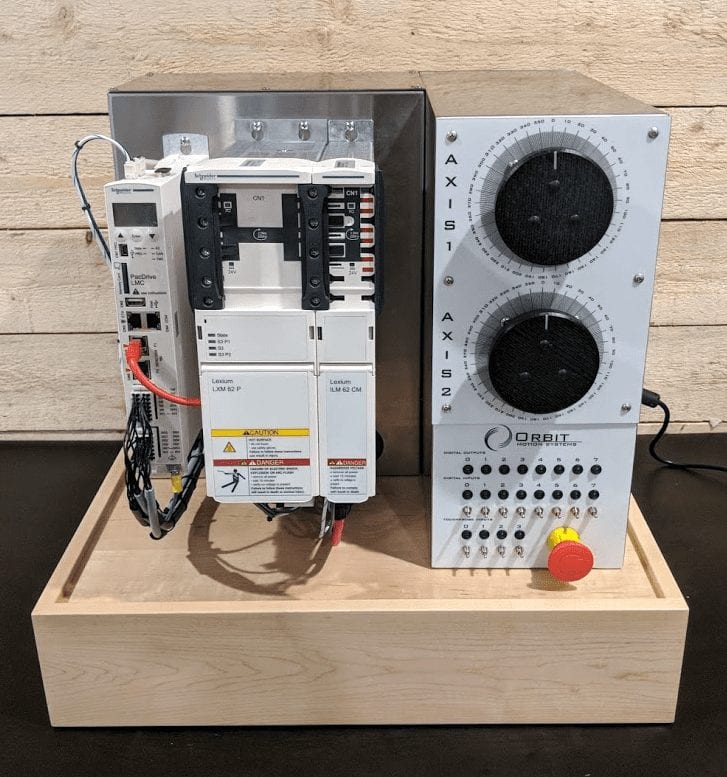

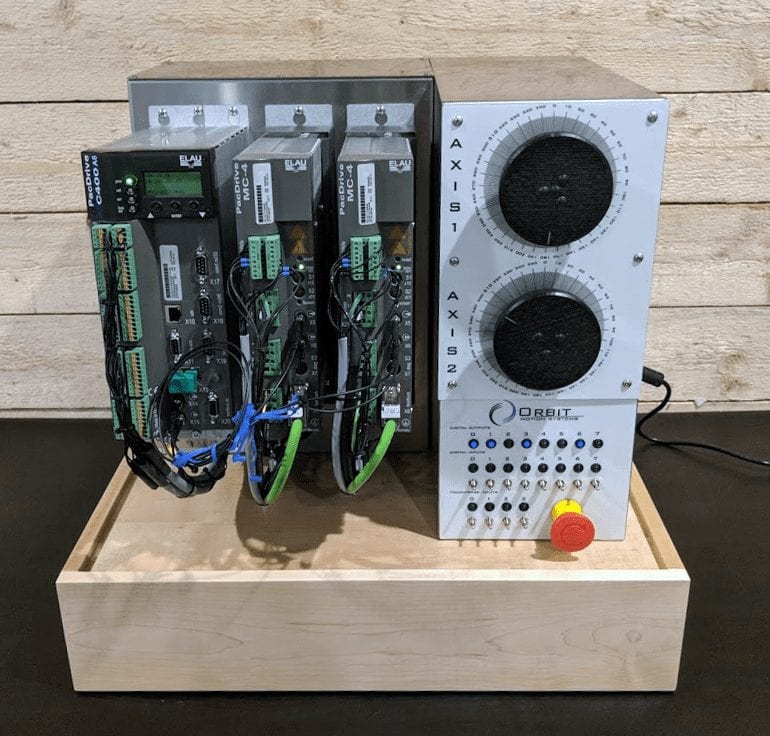

Custom Training Units

Want to continue learning in the Schneider environment after the training? Check out our custom fabricated training units!

- PacDrive 3 & M, and now LMC078/ LXM32 Units available!

- Test skills learned from SoMachine, SoMachine Motion, and EPAS-4 in a safe closed environment before making changes on your system

- Training units made to customers needs. Can be customized to utilize customers common products which can be used as spares in emergency situations

- Customers with Orbit training units may be eligible for discounted training