BACKFOLDING SOLUTIONS

Turnkey retrofit systems for Bobst, Post, Jagenburg, Signature, International, and many others.

We provide servo solutions for all types of businesses. One of our main specialties is backfolding systems for various types of folder-gluers. We provide retrofits for mechanical backfolds and outdated servo systems. Backfold solutions for both carton and corrugated folder-gluer systems. Turn-Key backfolding solutions available!

STANDALONE BACKFOLD OR TOTAL MACHINE PACKAGE

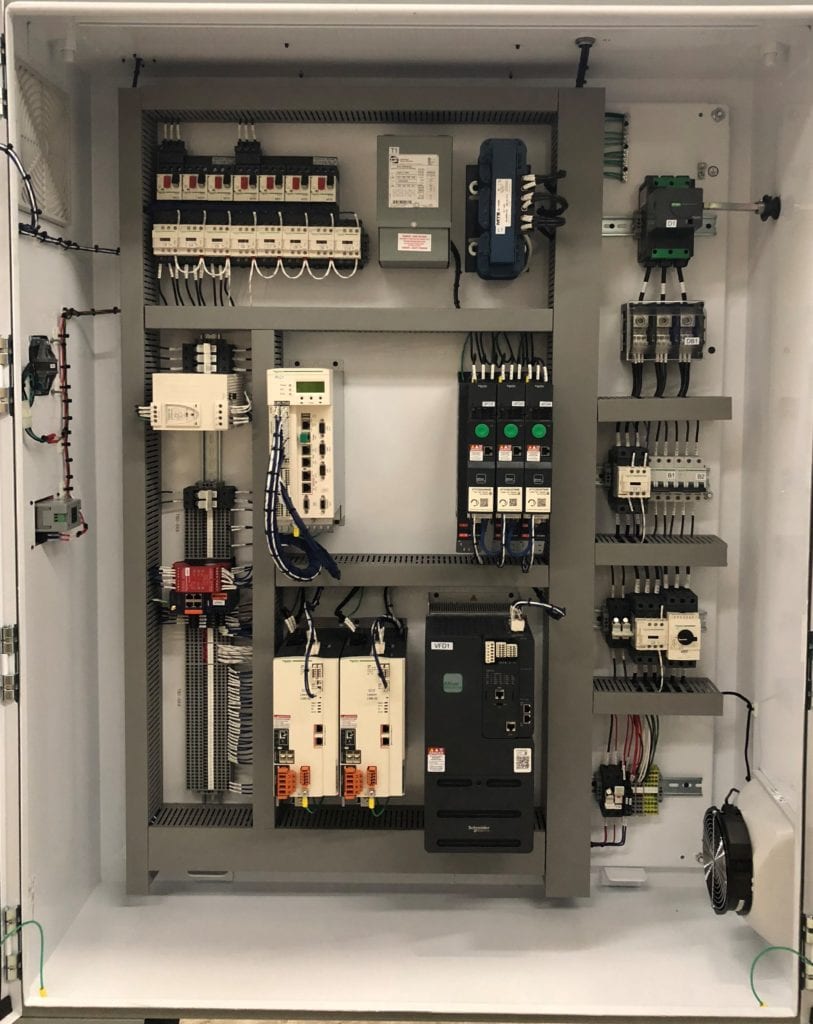

Aside from standalone backfolding we can also offer a total machine control package. Replace your old obsolete electronics with the latest hardware. New hardware includes:

-

Main motor and feed controls

-

Carrier controls

-

Machine operation with touchscreen control

-

Main cabinet wired to the latest in safety specifications

We are able to customize our system to fit your needs whether a complete package or partial retrofit.

BackFolding Overview

– Simple Parameters

– Easy to use HMI Touch Screen

– Excellent customer service

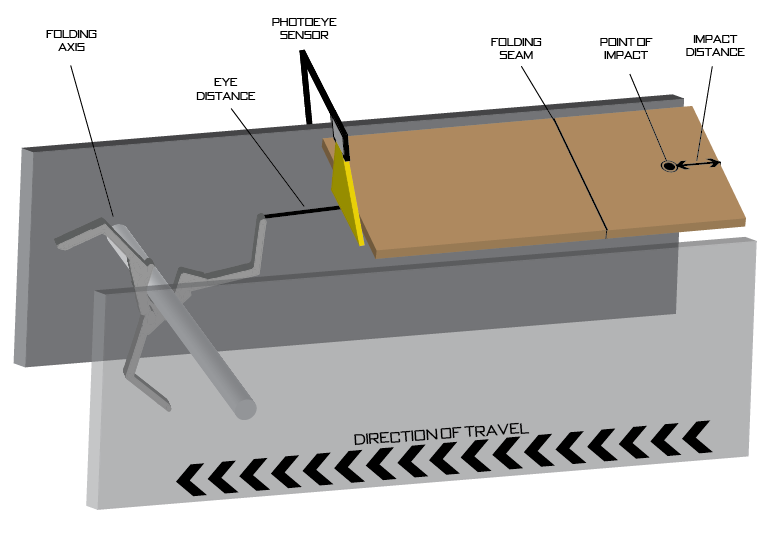

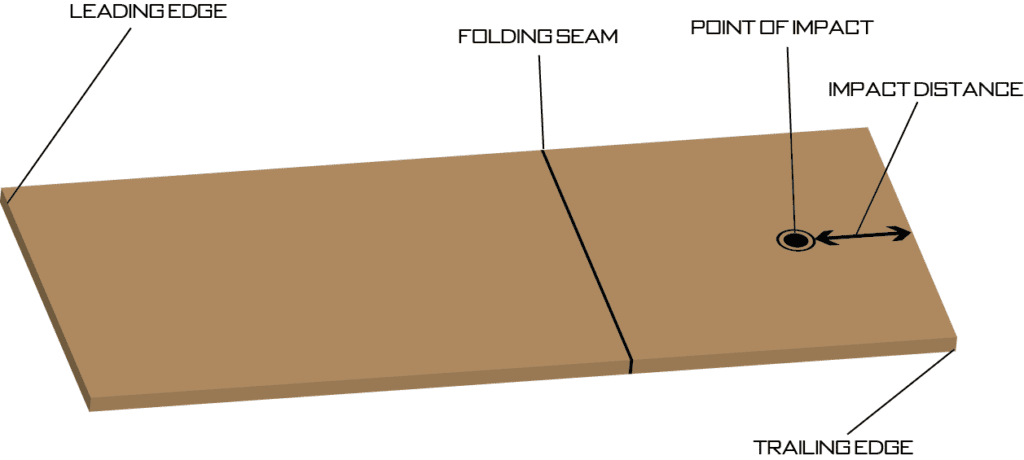

The basic operational sequence of the system is as follows. The product to be folded passes through a sensor for each folding station. When the trailing edge of the carton has passed the sensor, the folding sequence begins. The fingers will hit the blank at the point of impact. The point of impact is defined by the distance from the trailing edge of the blank. This parameter is set on the home screen of the touch screen interface (HMI). The angle of the fold, “fold angle”, is also set on the home screen. The fingers will then momentarily pause to allow the product to escape from under the fingers (Escape Distance) before returning to the home position and await the next carton. Synchronization to the speed of the feed belt is achieved through the use of a high-resolution encoder mounted on the main belt or pulley.

CONTACT US FOR A FREE QUOTE